The Automated Pit Designer was developed by a mining engineer, for mining engineers. Operating parameters such as minimum mining width and material digability are direct inputs which can be manipulated to create operational designs. The design parameters – batter angles, berm widths, and pit slopes – can vary by location and direction, allowing for extremely fine control over the projections.

Benches can vary by elevation and height allowing for arbitrary bench configurations including double benches. The design contours are extremely flexible. Contours can serve as a base for further design work or be used to generate more accurate pit-by-pit graphs and long term schedules. The Automated Pit Designer allows mining engineers to transform optimized block model results into operational mine design contours in a matter of seconds.

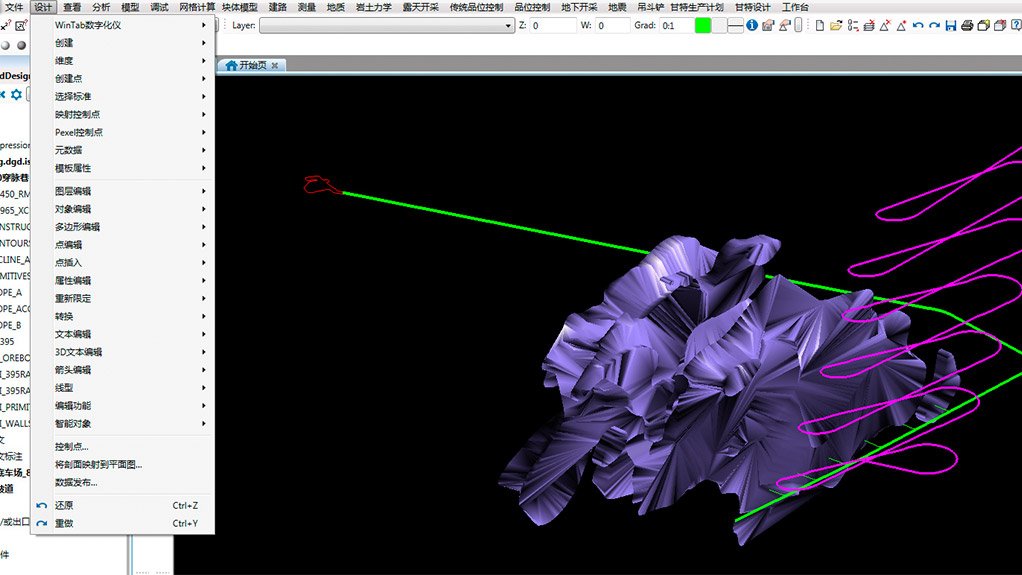

MAPTEK VULCAN SOFTWARE

With the accumulated knowledge behind Vulcan to draw on and guidance from experienced software engineers, the Automated Pit Designer was born. The world of commercial software development is quite different. I had previously only programmed research software some plotting utilities for multivariate geostatistics, a couple of block model utilities, and a Lerchs-Grossmann based pit optimizer. Of course, ideas are easy – actually doing something is much harder. These curves could then be informed from the block model, and the idea for the Automated Pit Designer began to take shape. As my research continued, I realized that most pits could be described by relatively few parametric curves, each consisting of relatively few control points. This research led to strong appreciation of the complexity of open pit mines, and the flexibility that an automated design tool would require. I reviewed all the open pit mines I knew of and worked at, and looked at satellite images on Google maps to find more.

With these challenges in mind, I began investigating the geometry underlying open pit mines.

MAPTEK VULCAN MANUAL

Also, the current process for contouring an open pit mine is manual or semi-automated, and can be tedious. This disconnect, between the geologic model and what actually occurs in the mine, can lead to unrealistic results and erroneous decisions. This is optimistic it assumes perfect extraction of cuboid blocks with little consideration for design parameters such as minimum mining width, digability, and local geotechnical conditions. In my role as a mining engineer specializing in open pit mine optimization, I frequently engage with clients struggling to generate open pit mine contours effectively and efficiently.Ĭonventional ultimate pit optimization operates on a discrete block basis classifying blocks as extracted or left in place. A great example of this is the work we’re doing with the Automated Pit Designer which will be released in Vulcan 10. One of the ways that Maptek continues to innovate is by revisiting old problems with new technology and fresh eyes.

0 kommentar(er)

0 kommentar(er)